Topic(s):

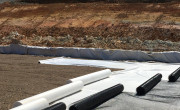

Contact Energy’s development of the Te Mihi steamfield, which is being as built by Hawkins Infrastructure, is to future proof their steam and injection requirements for the current Wairaki and the planned Te Mihi Power station.

The steamfield has approximately 10km of insulated steam and injection pipework running above ground linking the production and rejection zones of the Te Mihi geothermal reservoir. This will be achieved via a pump station, mechanical control centre, steam separators, dump station and dump pond. This is an integrated system to manage the geothermal fluids flowing to and from the power stations.

The design of the pump station included the requirement for certain environmental controls to be put in place. In the case of oil spills, Humes' API Oil Interceptors have been installed underground to capture and separate waste oil from water should in the unlikely event of an oil spill occurring from the pumps while pumping geothermal fluids to the various injection areas.

“The API Interceptors that have been installed are one of the largest models in our range,” said Chris Thorpe, Environmental Engineer for Humes. “This model, the API 5500, is 5.8m long x 1.8m wide x 1.8m deep and has a capacity to store 5,500 litres of hydrocarbon per unit. API Interceptors comply with the performance requirements of Ministry for the Environment’s environmental guidelines for water discharges from petroleum industry sites in New Zealand.”

Other applications:

- Service stations

- Truck stops

- Vehicle service centres

- Terminals and depots

- Blending and manufacturing plants

Features:

- Efficient separation, industry compliance

- Full range to suit individual catchment areas

- Emergency shut off

- Few moving parts

- Quality pre-cast unit

- Designed to carry legal wheel loadings