Topic(s):

Product: Humeceptor™ MI 9, Submerged Outlet

Retro-fitting stormwater treatment devices to existing drainage systems can prove challenging, especially in situations where outlet pipes are drowned. Such was the case when Humes was approached to provide a custom design using a Humeceptor™ unit for Lake Taupo's Nukuhau Marina improvements.

With typical free hydrocarbon removal rates of 97% and fine sediment removal rates in excess of 75% it was determined that a Humeceptor™ MI 9 unit was the ideal choice, especially given that Humeceptor™'s treatment ability has been proven by both full scale laboratory testing as well as monitoring of actual installations.

Though Lake Taupo experiences seasonal water level fluctuations the normal lake level meant that the outlet pipe would be permanently, partially submerged. Also the unit had to be configured to accept two inlet pipes from which untreated stormwater would be received, one new and one pre-existing.

The “submerged” Humeceptor™ configuration involves adjusting the internal weir height to maintain a hydraulic head differential between inlet and outlet pipes. Normal pipe invert drop across a standard single inlet STC 9 unit is only 25 mm making Humeceptor™ ideal for retrofit to existing drainage systems. The submerged configuration with multiple inlet pipes requires the slightly larger invert differential of 75 mm but this was still easily accommodated in the case of the Nukuhau Marina installation. By selecting a Multiple Inlet (MI) configuration it was possible to eliminate the need for an upstream, combining manhole structure, which saved cost as well as removing hydraulic loss from the system.

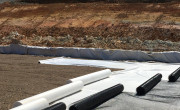

The installing contractor, Fulton Hogan Taupo, faced significant practical challenges when it came time to install the Humeceptor™. With normal lake water level less than two metres below finished ground level and the position of the treatment devices less than 10 metres from the lake’s edge, the water table was similarly very close to ground level. As soon as the receiving pit was excavated it flooded with water and with Lake Taupo as a water source de-watering was not an option. Fulton Hogan’s solution was for Humes to supply a custom built treatment chamber that could be sunk as a caisson and have its base cast in-situ once the desired chamber depth was achieved.

The submerged MI 9 Humeceptor™ unit has a hydrocarbon capture and containment capacity of 1,900 litres as well as sediment storage capacity of 6.81 cubic metres. The availability of these storage volumes were important features for ensuring adequate containment was provided for captured pollutants originating from the busy marina site.

Maintenance of Humeceptor™ units is carried out by a vacuum truck from ground level, i.e. no confined spaces entry is required. For typical hardstand situations these containment volumes would permit 12 monthly maintenance frequency though this can vary depending on site specific pollutant load.

Kor-n-Seal rubber boots are supplied as standard features for connecting inlet and outlet pipes to the Humeceptor™, as they provide fast connection and a watertight seal without any epoxy. Additionally, boots provide flexibility for any potential settling movement that might be experienced after installation.

The resulting installation of the MI9 Humeceptor™ unit has given the marina’s managers the security of knowing that the potential for contaminants such as fine sediments and hydrocarbons spilling into the receiving stormwater environment has been dramatically reduced.

Humes’ current range of water quality treatment devices can now play a key role in providing solutions in a variety of environmentally sensitive areas. With Humes’ commitment to developing and obtaining technology in water quality, rest assured there are more solutions in the pipeline.